|

|

Jaguar Nikasil & Sulfur

As you know I have been working on gathering information related to

Nikasil and the problems that the early Jaguar aj26 xj 8 & xk8 had with

it. I first covered Nikasil and what it is and the applications and

problems related to it in the past. I also covered a part two in an

effort to explain the effects of cylinder washing most related to

Nikasil engines. And now this third part to cover the many

misconceptions and the clarification of Nikasil, Gasoline & Sulfur.

My first detailed information on Nikasil was based on historical

information made available to me. I since realized that some of that

information was not correct so I began investigating it further to pull

together real information relating to the use in Nikasil engines. As you

know Sulfur is a normal product of fuel products (Gasoline) and is

normally removed in the refinery stage prior to the process of make

gasoline or adding octane. The one thing I did not realize was that bulk

fuel is used to make hi & low octane fuels so the myth that hi octane is

better for the Nikasil engine is just that a myth because it contains

the same amount of sulfur as regular. Several months ago under the

impression that hi-test fuel had less sulfur (based on articles I have

read) I suggested that hi-test fuel was better for the Nikasil engine

block and was challenged and oh boy was I wrong. So I began my

investigation and this is what I found.

I acquired this information from 3 sources and I had two questions.

1 – What was the sulfur content PPM in the year 2006?

2 – Does the octane level affect the sulfur content (PPM) in the fuel?

This is what I got. I will place this information on this discussion as

I receive it.

Response 1

First, as background, I need to describe the regulatory situation in the

US. Prior to the advent of unleaded gasoline’s, there were few

governmental regulations pertaining to gasoline properties. The

consensus specification then was ASTM D439. Most oil companies adhered

to D439 and some states adopted it as their standard. D439, as

oxygenated gasolines became wide spread, evolved into D4814, the

standard that continues to this day. It is primarily a performance

standard and does not address the components of the fuel blend. But it

is frequently updated to reflect current federal and state regulations.

And, it is referenced by many states in their regulations. Beyond the

ASTM standard, we now have both Federal and state regulations. States in

air quality nonattainment areas sometimes have special regulations for

those areas requiring fuels with special properties, like lower vapor

pressure or lower sulfur content. Those special regulations are termed

state implementation plans (SIPs) which have to be approved by the

Federal EPA. And, in addition, the EPA has many of its own regulations

governing fuel specifications.

Sulfur

D439 and early versions of D4814 had sulfur specification limits set at

0.1 Wt. %. One can think of that spec as 1000 ppm (parts per million)

although, with allowable rounding, it could have been as high as 1049

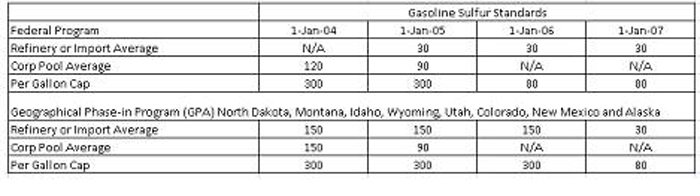

ppm. In 2001, the EPA finalized a gasoline sulfur rule that limited the

per gallon cap on sulfur to 300 ppm, starting in 2004. In addition to

the cap, the average had to be below 120 ppm. In 2006, the sulfur

content requirement was reduced to 80 ppm, with a refinery average of 30

ppm max. and it remains at that level today. I'll note that there were a

few exceptions made for small refiners and certain geographies in the

mountain states that either had relaxed standards or a longer time frame

to comply. But typical sulfur levels for both grades, regular and

premium, will be somewhat below the 30 ppm figure. In California, the

current sulfur limit is 30 ppm, on a per gallon basis, and the average

must be below 15 ppm.

Now at this point I contacted the EPA (twice) and they offered me what I

expected an answer that no value. They offered me the regulations and

had nothing on the real measurements. To think I am paying their

salaries! I then contacted two other states and asked if they could tell

me one told me that in the year 2006 the sulfur was measured at 300ppm

The other had no idea what I was asking for and gave me the number for

the EPA and I live in that state!!!!

Response 2

EPA regulations require that all gasoline sold in the US meet the same

sulfur specification. Gasoline produced at a refinery must average a

total sulfur content of 30 mg/kg on an annual basis with no batch of

gasoline ever allowed to exceed 80 mg/kg total sulfur This sulfur

specification applies to all grades of gasoline sold in the US.

In a gasoline-powered spark-ignition combustion engine, combustion is

initiated by a spark from the spark plug and ideally combustion should

proceed smoothly throughout the combustion chamber around the spark.

However, if the gasoline undergoes spontaneous combustion in the

combustion chamber separate from the spark, smooth combustion cannot

occur and a pinging sound may be heard from the engine. This phenomenon

is called knocking and can seriously damage the engine. The octane

number of gasoline is a measure of the fuel's resistance to

auto-ignition, that is, the fuel's resistance to knocking, where a

higher octane number is better.

Regular unleaded gasoline (RUL) in the US almost always meets a minimum

octane requirement of 87. Mid-grade unleaded gasoline (MUL) has a

minimum 89 octane, while premium unleaded gasoline (PUL) has a minimum

91 octane; some companies offer PUL with a minimum 93 octane.

The minimum octane requirement for a particular vehicle is recommended

by the vehicle manufacturer. For vehicles with typical compression

ratios, the octane provided by RUL is usually sufficient. However, some

vehicles (such as higher performance vehicles) with higher compression

ratios have a greater tendency to knock because of higher pressures and

temperatures in the combustion chamber. Manufacturers of such vehicles

usually recommend the use of a higher octane grade

of gasoline.

Now that I had the sulfur information I began asking what is it that

makes it a real problem with a Nikasil treated engine block. What I

found out is that sulfur and water create H2S03 and this equals sulfuric

acid. Yikes! It is now pulling together and making better sense but I

had a problem with the water. So I called engine shops and asked for one

of the technical advisors and asked how could moisture get into the

cylinders? He asked me if I ever saw the white/clear exhaust that is

produced when you first start your car? This is moisture from the

combustion chamber of the engine. I began to look back on my experience

with compression and rapid expansion. Now I got it! This explains the

concerns over the sulfur, short trips. I asked if this is a problem when

the engine is at operating temperature and he said no. I then asked

about cylinder washing what I was told is that poor fuel presentation

into the cylinders is on most part the problem. When an injector is

dirty and presents a stream and not a spray. I asked if the it was a

problem that could be caused by an improperly programmed ignition system

and he felt it could be.

All this information could freak people out about nikasil it would me. I

truly feel that if you have a compression check and it is good you have

a good car. You should make sure that you let the engine reach operating

temperature before shutting down, be sure that you maintain it by

changing the oil, have the TSB’s complied with and that your injectors

are clean and operating properly. I should also note that you should not

over use injector cleaners! They often have a limit on how often you can

use it. Using higher octane fuels will offer you a cleaner operating

engine hence the reason for suggesting the use of higher octane fuels.

A good read about

Blow-By

|

|

|

|

You should follow

JagRepair.com on Twitter

See us on Facebook

|

|

|

|

|

Please support JagRepair.com

|

|